Unlike the rest of the equipment in your bag, the golf ball is still largely made in America. Not

Taiwan, Malaysia, Vietnam or China. Rather, it’s New Bedford (Titleist) and Chicopee (Callaway) in Massachusetts. Or Covington (Bridgestone) in Georgia. Or Liberty (TaylorMade) in South Carolina. About nine out of every 10 premium golf balls sold come from one of four factory towns in three US states.

Each of these operations mixes the highly technical elements of modern golf-ball manufacturing with workers whose multi-generational legacies often stretch back to the Great Depression. It’s these sophisticated manufacturing enterprises that have become the pride – and in some cases, the engine – behind these small towns, and in turn these small towns continue to propel the biggest ball companies, making a combined half-a-billion balls a year.

This in a day when American manufacturing has somewhat fallen away. US manufacturing jobs decreased by a third in the first decade of this century, most painfully in the fringe towns, where products once thought essential to the landscape and character of a region are increasingly built overseas. Amid all of that, the golf-ball business resists and persists. When you ask officials at these companies or in these towns why the world’s golf balls are still made here, the answer is consistent. As proud as they are of their technological processes at plants that operate multiple shifts a day, seven days a week, they’re prouder still of a simpler asset. Like Chicopee mayor Richard Kos says: “Natural resources have made the United States a great country, but the resource that’s special now, the resource that’s special here, is the human resource.”

This is not a story about golf balls. This is a story about people.

Titleist

New Bedford / Massachusetts

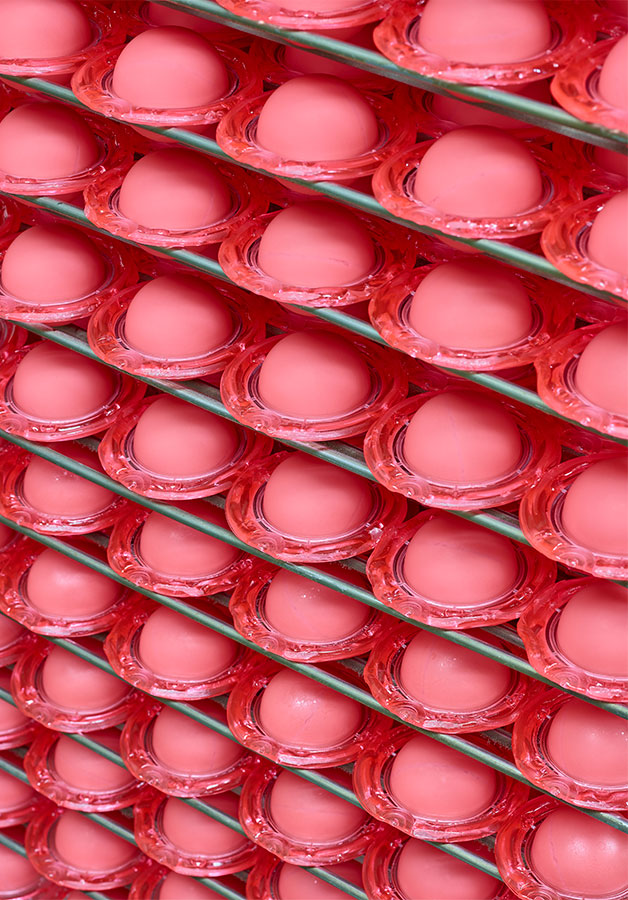

The familiar story of Titleist, whose legendary Pro V1 franchise accounts for about three-quarters of the balls played in professional golf and one of every four balls sold in the United States, begins with a missed putt from company founder Phil Young that led him to question the quality of the ball he was using. That led to a commitment to manufacturing precision that remains the company’s guiding principle. (Example: Titleist has been X-raying balls for perfectly centred cores since the one-time rubber-processing company got into making golf balls in 1932.)

It’s not an exaggeration to say that no company in the world makes more balls at a higher quality than Titleist. One reason: the 1,200 employees in its ball operations reflect an aggregated 23,000 years of ball-making experience. The company’s personnel at all levels of R&D and on the plant floor interact daily. It’s not happenstance that Titleist’s R&D, manufacturing, testing, custom-logo and distribution facilities are located within a 13-kilometre circle.

“This type of manufacturing, it’s not linear,” says Bill Frye, senior vice-president of golf-ball operations, who came to Titleist from Boeing 28 years ago. “It’s an integration. And there’s a certain pride in knowing you’re not just a cog in the wheel. Somebody on third shift grinding cores knows they’re an important part of the ongoing success of the future of the company.”

It’s that manufacturing agility that allowed a company whose top product was a tour-played ball with rubber windings to switch to solid-core, multilayer constructions with the introduction of the Pro V1 in late 2000. If it seemed like that process happened overnight, credit a workforce that has been there and done that. Manny Baptista met his wife at Titleist; he has worked with his brothers there. After 37 years in, going to work still feels like coming home. “Honestly, it’s peace of mind coming here,” he says. “Unlike everyday life, any chaos that happens here is under control.”

That culture might be at the foundation of Titleist’s ball business, but when the company was bought by Fila, a Korean-owned sports conglomerate, in 2011, there were rumblings the business might move overseas. It didn’t, and today the impact on the region, as well as Acushnet, the parent company of Titleist, is not just emotional. In addition to the local hospital system, Acushnet is the area’s largest employer and likely its largest benefactor. The economic impact of its payroll alone is estimated at half-a-billion dollars. You can purchase new machines and a new building in a new country, but you can’t buy a culture.

monitoring the specifications of each dimple to two-ten-thousandths of an inch.

“As part of any good business, you had to go through the exercise and evaluate,” says Peter Broome, senior vice-president of industry and trade relations for Acushnet. “But quickly you realise there’s so much more to the general ledger here than economics. You can always find a reason to move manufacturing processes, but the fact we’re where this thing started matters.”

‘You can purchase new machines and a new building in a new country, but you can’t buy a culture.’

Mike Gemaly was nearly born on the old winding-room floor where his mother worked at the original Ball Plant I. He has been making golf balls for 36 years and is one of more than 50 employees with quarter-of-a-century’s worth of experience. He commands the room like the rock star he once left town thinking he would be. But as life happened, he came home and eventually got his GED through Titleist. He and Manny and those around him know what the company has done for them and vice versa. Titleist might be the No.1 ball in golf because of its success in the market and on the world’s professional tours, but the way players embrace Titleist’s products probably has a lot to do with the way its employees embrace their work.

“When we see a golf ball, we see our life, we see the people that we’ve been close-knit to,” Gemaly says. “We see what’s allowed us to get things done in life. This isn’t just a golf ball. It represents too much for that.”

Callaway

chicopee / massachusetts

Vince Simonds, whose father, Jim, started in 1948 at the same ball plant that his son now runs, knows things could have gone another way in a town where Spalding/Top-Flite and now Callaway have been making golf balls since 1896. “It was really bad,” he says, reflecting on the early 2000s, when Wall Street investors purchased Spalding/Top-Flite and ultimately filed bankruptcy for Top-Flite. “People who had been working here for decades lost their pensions. There was just so much uncertainty. We had over a thousand employees, and we got down to 125. But I knew I didn’t want to be the guy locking the doors here and watching the parking lot fill up with weeds.”

transfer rubber slugs and finished cores to and from the moulding machines

at the Chicopee plant that’s more than a century old.

Callaway had purchased the company from bankruptcy in 2003, but there was a moment after the recession when it appeared the plant would close and the company would move its golf-ball production to Mexico and China. But when Callaway president and chief executive Chip Brewer took over the company in 2012, he chose to make Chicopee the fulcrum for Callaway’s re-energised golf-ball business, starting in 2015 with the Chrome Soft line of balls. The so-called “ball that changed the ball” helped double Callaway’s ball business and move it from No.4 to No.2. “We took a different tack,” Brewer says, “and we’re really only tangentially starting to see the benefits of what we’re spending there at this point.”

Callaway has reinvested in its US-based ball business, spending $US50 million over three years. Now, the newest highly automated robots work with union workers from the Boilermakers Local 1851 to build the first ball that uses Nobel Prize-winning graphene in its cores. Chicopee is reinvigorated. The street leading to the plant now features commercial investment and a new Dunkin’ Donuts, and the local bus route was saved so that factory workers can get to the plant more easily. A new hotel did $US70,000 last year just from Callaway business.

Simonds says that comeback is about the pride of a region that had seen more than a third of its manufacturing jobs disappear in the first 15 years of this century. Lifestyles weren’t merely changing, the area was on the verge of economic collapse.

Working with state and local officials, the Callaway plant now has worker training programs with area community colleges. Simonds says a big portion of the millions of dollars of investment in the plant has had local economic effects for electricians, mechanics, programmers and others. Kos, about to step down after his second stint as Chicopee’s mayor, was mayor when the old plant fell victim to bad decisions and a worse economy.

“Callaway saw the level of productivity of the people who were still here as well as the ones who came and learned from example, and that has made this facility able to be something that a publicly traded company can justify,” says Kos, a lifelong resident who remembers the days when tour pros like Lee Trevino would come to the factory and hit balls at nearby Annie’s Driving Range. “Nobody in that financial environment cares about Chicopee or even the golf ball. They care about the bottom line and how do you justify it.”

Simonds measures progress in the Chicopee plant a different way than the new technology and the expansion of the current building. He sees progress in simply how hard it is for him to remember every employee’s name in a plant that now has more than 400 workers.

“We’re golfers, love the game, love the business and wanted to stay in it,” he says. “There were a lot of financial people looking at numbers saying there’s got to be a cheaper, more economical way to do this. But there are intangibles to it. There’s a lot of knowledge on the factory floor. You just can’t Google ‘golf-ball-making machine’ and expect it to work. You need that history behind you to be able to develop systems and processes to do it correctly and profitably.”

‘There’s a lot of knowledge on the factory floor. You just can’t Google ‘golf-ball-making machine’ and expect it to work.’

Bridgestone

covington / georgia

DAVID Bernd was a 34-year veteran of Kimberly Clark and remembers the security briefings the company issued to employees travelling to Augusta, Georgia. “Most people would fly into Atlanta and drive to Augusta via I-20,” Bernd says. “They made a point of telling us not to stop here.”

“Here” is Covington, Georgia, a town of some 13,000 people 55 kilometres east of Atlanta. Bernd serves as the vice president of economic development for Newton County, of which Covington is a part.

Covington is known as the “Hollywood of the South”, a moniker bestowed on the city for the high number of television shows and movies filmed there. The city’s Homer Sharp Stadium also served as the setting for the final football scene in “Remember the Titans”. Just as Coach Herman Boone’s Titans overcame adversity to thrive, so has Covington. With Bridgestone Golf playing a leading role.

Like an anchor tenant in a shopping centre, Bridgestone – the Tokyo-based tyre, rubber and sports giant that opened a US marketing office in Covington in 1985 and started manufacturing balls there in 1990 – helped attract other businesses to the area.

“Every Japanese executive that comes here plays golf and knows Bridgestone,” Bernd says. “We make it a point to take them there to get ball-fit as well as golf balls with their logo on it. When they go back to Japan, they’re aware Bridgestone is in Covington. It’s a powerful recruitment message.”

Five hotels within eight kilometres of Covington are in the design stage. The Covington Town Centre, including offices, townhouses, a theatre and a Publix, is under construction. Facebook is creating a $US42 billion data centre in nearby Stanton Springs in what could be the largest economic-development project in the state’s history.

“None of this could have happened without the foundation the Japanese companies, particularly Bridgestone, laid 30 years ago,” Bernd says.

Dan Murphy, Bridgestone Golf’s president and chief executive, is a longtime Covington resident who has seen the distressed side of the area and now is enjoying witnessing the investment.

In 2014, Murphy helped drive the decision to make all of the company’s premium balls in Covington. Believing in golf balls “made here, played here” helped boost the number of employees to its current 173, with close to 90 percent living in Covington or its outskirts. All of Bridgestone’s television commercials, including current ones featuring Tiger Woods and Bryson DeChambeau, were shot in Covington.

But Murphy and Bridgestone do more for Covington than lead with their logo. Murphy and Bernd are proponents of BHAG’s: Big Hairy Audacious Goals. In the instance of Covington, that goal is to eradicate poverty and get to zero unemployment. The key to achieving that: education.

“The state estimates how many beds it will need in its prisons by the number of kids who can read by third grade,” Bernd says. “Our schools were not good. In 2012, we had a sub-60-percent high school graduation rate, and 80 percent of our kids read two grades behind their grade level.”

A reading program involving 600 volunteers, including a large number of Bridgestone employees, started in 2013. Since then the graduation rate has topped 90 percent, with Eastside High School receiving an A ranking nationally for the first time. It’s a fundamental shift in personal economy, too. Median wages in Covington are now nearly $US60,000. Nine-year Bridgestone employee Dennis Johnson has seen it firsthand, starting as an entry-level cure press worker and now overseeing 18 people on his shift. A former Harley-Davidson employee with inked-up arms, a strong Southern drawl and a quick wit, Johnson lives in Covington and revels in the pride of working there, particularly on the Monday after last year’s Masters.

“It’s Tiger Woods, and we made his golf ball,” Johnson says. “We all have a part in that, from the person receiving the rubber to the person shipping the ball out the door. Put your name on it and be proud of what you do.”

‘It’s Tiger Woods, and we made his golf ball. We all have a part in that… Put your name on it and be proud of what you do.’

TaylorMade

liberty / south carolina

Despite its patriotic name, Liberty was – and in some ways, still is – facing the unpatriotic fate of becoming a dying Southern mill town. On the main drag of Front Street, a dozen red, white and blue “Welcome to Liberty” banners hang from telephone poles, a stark juxtaposition to a street with numerous boarded-up buildings. Around the corner is the rarest of sights in the rural South: a deserted church. A grim symbol for a town fighting for its soul.

With slightly more than 3,000 people, Liberty sits in the upper north-west corner of South Carolina. The closing of the Liberty Denim plant in 2011 dealt a blow to an already shaky local economy. The median income was $35,986 for 2013 through 2017, according to US Census estimates.

A few kilometres away is the Pickens County Commerce Park – a relatively confined area, but one of significant growth and development during the past decade. Included is TaylorMade’s 11,000-square-metre ball plant that opened in 2014. It wasn’t always a sure thing.

Scott Austin is the plant manager. He came to the company in 2006 when TaylorMade’s ball plant was in the old Dunlop facility 50 kilometres away.

“My expertise was moving plants,” Austin says, sitting behind a desk littered with custom and cut-open golf balls. “A few months into the job I heard we were moving the urethane line to Taiwan. So, yes, leaving South Carolina was talked about.”

But in 2012, TaylorMade’s revenues surged with the RocketBallz metalwoods phenomenon, giving management the financial confidence to go ahead with a new building in the United States for its golf-ball business. TaylorMade invested $US13 million to build the plant, using local contractors and suppliers during the construction. It started with about 80 employees when it moved to Liberty and now has 230. In all, Ray Farley, executive director of Alliance Pickens, estimates the economic impact of TaylorMade coming to Liberty to be in the eight figures.

Sixty-five percent of the tax revenue goes towards funding schools in Pickens County. One of those schools is a technical high school that’s among the top 1 percent of its kind in South Carolina. The school trains talent that TaylorMade and other state businesses need. “It’s the private sector contributing to education, and education contributing to the workforce of the private sector, which then contributes to economic development,” Farley says. “That tax revenue feeds that circle.”

Although the area still faces challenges, there are reasons for optimism. The number of employees in Liberty has increased 9 percent, the median household income is up, and poverty, while still above the national average, has fallen nearly 2 percent, according to datausa.io.

“We have one area with the past and then this other area where there is the future, hope and growth,” says Ken Roper, a Pickens County administrator who has lived all his 50 years in the area. “Without these companies, including TaylorMade, there might not be a reason for this town to exist. Pride is important for a small town. This community works hard. They make things with their hands. They want to be hopeful for the future. Now that hope is back.”

‘This community works hard. They make things with their hands. They want to be hopeful for the future. Now that hope is back.’

Janice Holland, a 32-year veteran of Dunlop and now TaylorMade, who started out earning $3.35 an hour, knows about hope. She’s back at the plant after a two-year battle with cancer, and she now has two sons working in Liberty with her. “You invest your life in a company, and you notice everything,” she says. “We’re family here, and this is a good job. We’re making a product here in the USA. You don’t walk away from that.”

Holland works in the custom-tour department, sending product out to the tour staff. She makes it a point to put notes in each box, telling Rickie Fowler or Jon Rahm or Rory McIlroy that she’s cheering for them. Then, like she does in church, there’s a prayer for each of them to have a blessed day. Blessed. Whether the church is boarded up or not.