IT’S funny how small ideas can turn into big ventures.

When Ping founder Karsten Solheim decided to help a few tour professionals improve their game by calibrating their equipment to fit their size and swing tendencies during the 1960s, little did he know he would start a revolution.

Using the player’s favourite club as a starting point, Karsten fine-tuned the loft and lie of every iron to give each professional a perfectly matched set of sticks. When those few players went on to win tournaments in quick succession it was a lightbulb moment for Karsten, confirming his belief that properly-fit clubs were actually key to optimising a golfer’s performance.

“Those were the days when the vast majority of golfers were using equipment purchased off the rack without any consideration given to their individual size or swing tendencies,” says Ping’s product manager in Australia, Colin Field.

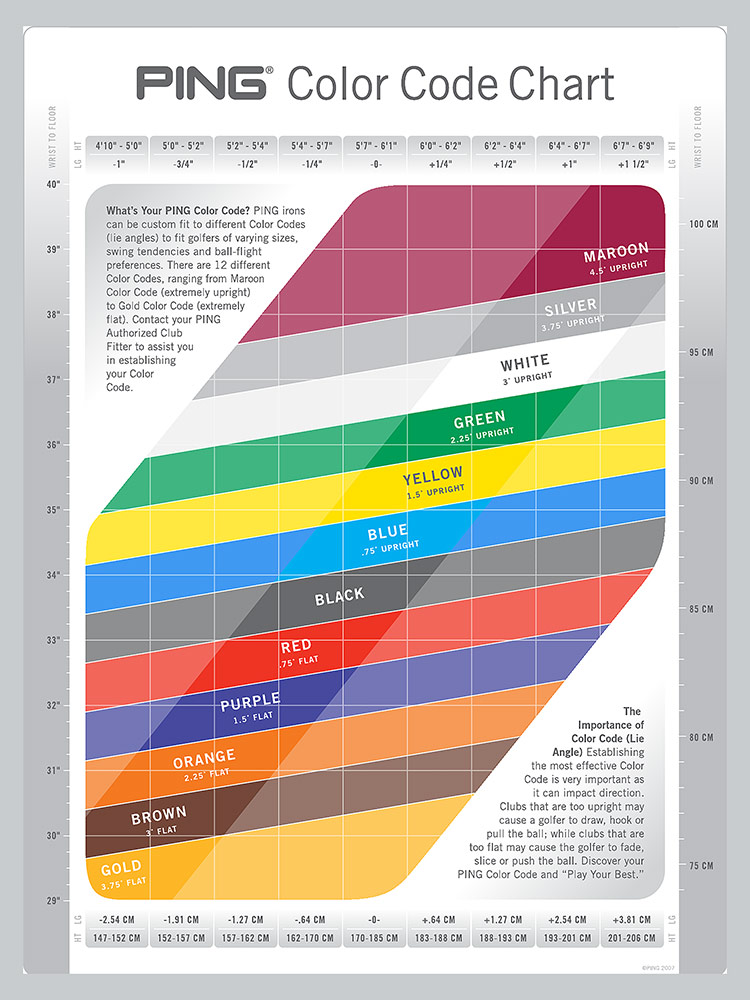

Sensing an opportunity to differentiate his fledgling brand while helping golfers lower their scores, Karsten quickly began work on his famous Ping Colour Code system which debuted in the early 1970s, offering a simple, effective way to match a set of clubs to each individual through custom fitting. The idea behind the colour codes was they would represent different lie angles, and Ping irons would be custom-fit to these colour codes to match golfers of varying sizes. Of the 12 colour codes in total – ranging from maroon (extremely upright) to gold (extremely flat) – Karsten thought it was critical to establish the most effective colour code for each customer as clubs that are too upright may cause a golfer to draw, hook or pull the ball, while clubs that are too flat may cause the golfer to fade, slice or push the ball.

Ever wondered why Ping stamps their irons with a coloured dot around the hosel? That represents where the owner fits within Karsten’s colour code.

According to Field, such attention to detail and service from the company hasn’t changed in 50 years.

“Today, custom fitting remains a central focus of everything we do,” he says. “Our engineering, manufacturing and assembly processes are developed to ensure innovative, high-quality, custom-fit product. All Ping clubs that leave our factory are precisely calibrated to ensure performance.”

Field says while the basic clubfitting process “is more or less the same”, what has changed over time is the ability of the fitter to measure a golfer’s baseline and compare performance gains using technology like launch monitors.

“Technology coupled with adjustable clubs and an abundance of shaft options really enables the fitter to fine-tune a golfer’s ball-flight and feel,” he says.

Field, who has been with Ping for 17 years, has seen plenty of golfers come and go for new clubs. He says one of the biggest misconceptions about the fitting process is the time it takes to get the service you really need.

“It can be an intimidating process for those unfamiliar with the game but not every golfer needs a two-hour, tour-inspired fitting experience,” he says. “Golfers who are new to the sport or lack repeatable patterns in their swing may be better served by a static fitting, where a golfer’s height and wrist-to-floor measurements are applied to a chart to establish an iron’s length and lie. Ping’s Colour Code Chart has been developed based on tens of thousands of fittings and offers high statistical probability that the clubs will better match the golfer than buying off the rack.”

So what’s been the secret to Ping’s success after all these years since Karsten’s big idea?

“Work satisfaction,” says Field. “It’s a privilege to work for a family-owned company with an amazing engineering heritage like Ping. During my 17 years, I have been fortunate to work and interact with Solheim family, design engineers and tour players. What amazes me is the number of people who have worked at Ping for more than 25 years in all departments. It’s a very positive reflection on the Ping culture and shows that companies who treat their staff well can punch way above their weight.”

Did You Know?

There are more than 10 million possible combinations available with Ping irons. The Ping fitting mix, coupled with the following process, allows the player and fitter to identify an optimal model, colour code (lie angle), length, shaft, and grip. Detailed ball-flight analysis serves as the ultimate step in refining and confirming the final combination of model, colour code (lie angle), club length, shaft type and flex, and grip size.

How should someone prepare for a clubfitting?

Prior to a fitting it’s important to establish your goals from new equipment, says Field. “A player’s goal could be to get a higher flight, less fade, greater consistency or simply a more productive set combination. A good fitting should establish these goals at the commencement of the session.”

Once this is done, it’s advisable for the golfer to hit their current equipment to establish a baseline for distance, flight and dispersion.

“As fitters we can then test various options and should be able to demonstrate the gains in distance, flight and dispersion achieved during the club fit,” adds Field. “Golfers are often blindsided by distance and forget that they may be better served by optimising their ball flight and tightening their dispersion over a club which goes further but is inconsistent and has poor stopping power.”